RAPID PROTOTYPING

FROM PROTOTYPE TO PRODUCTION

Alpha Foundry now provides designers and engineers the ability to move quickly forward in pursuit of prototype, one-off, small batch, and production level mold and core production. 3D printed molds and cores enable faster delivery times, new design freedoms, and reduced costs by utilizing a digital, pattern-less workflow. 3D printing delivers castings with complex rigging designs and monolithic cores in days, rather than weeks or months, while saving money on patterns, molds, and labor.

- 356 and other aluminum alloys

- ZA-12

- Grey Iron

- Ductile Iron

Casting Dimensions: Up to 6” across parting line and 18” x 18” parallel to parting line for production Alpha Process Castings; 3D Sand Prototype Castings up to 24.

Casting Weight: Up to 20 pounds 356 aluminum, 40 pounds ZA-12, and 30 lbs iron for production Alpha Process Castings-3D Sand Prototype castings up to 150 lbs cast iron.

We start every project discussion with the goal of understanding the need and the application from the customer. From there we’ll systematically engineer and plan out a casting process that delivers ideal results very quickly-then implement that plan on schedule with clear communication and responsiveness to the customer throughout the process.

Benefits of 3d sand printing for your prototype

COMPLEX GEOMETRIES:

3D Sand printing enables the creation of intricate designs that would be difficult or impossible with traditional manufacturing methods.

COST-EFFICIENCY:

It reduces the need for expensive tooling or molds, making it a cost-effective option for prototyping, especially for small batches.

RAPID PROTOTYPING:

3D sand printing is cost-effective for prototypes, small series, and serial production. The price only increases with the amount of material needed.

FLEXIBILITY:

3D sand printing allows for more flexibility and the ability to shift directions quickly.

REDUCED WASTE:

Additive manufacturing minimizes material waste compared to traditional subtractive methods.

SCALE PRODUCTION TESTING:

Sand printing allows the testing of full-scale prototypes to verify functionality and performance before mass production.

Need a quote or estimate for your project, prototype or casting? We’re ready to help.

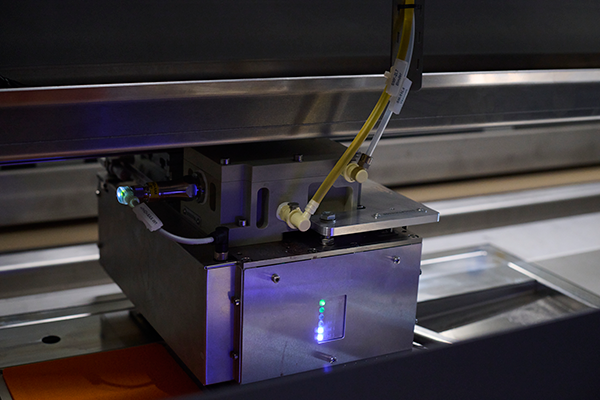

With the S-Max® we have increased capacity, enhanced production, and offer our customers more value.

Faster, more efficient shell sand castings. Translation: premium castings without a premium price.