Aluminum, Zinc, and Iron Castings THAT ARE AFFORDABLE, ACCURATE, REPEATABLE & COSMETIC

Alpha Foundry has a long history of innovation, exceptional quality, and trusted customer service. Our business is positioned to help customers at any level of their project, from initial start-up and accepting responsibility for a current project, to keeping your castings moving forward and filling in as an additional supplier. We are big enough to handle most needs, but small enough to narrow in and focus on your specific needs.

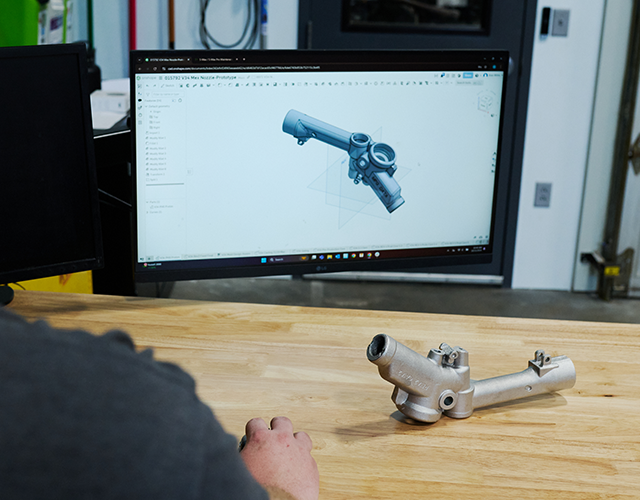

Our hybrid shell molding process – the “Alpha Process” – delivers impressive results that are not obtainable with conventional sand-casting technology. We also offer our innovative 3-D Core Production, which can unlock otherwise impractical or even impossible internal casting geometry while remaining cost-effective for production castings. Plus, our in-house Machining Services are available to deliver at any level, from start to a finished product.

Need a quote or estimate for your project, prototype, or casting? We’re ready to help.

HOW CAN ALPHA FOUNDRY HELP YOU?

Get faster delivery, design freedom, and cost savings with 3D-printed molds and cores. Receive complex castings quickly, sometimes even in a matter of days, rather than months waiting for pattern production. Alpha can take you from prototype to production all under one roof!

WHAT EQUIPMENT DOES ALPHA USE FOR 3D PRINTING?

Alpha Foundry’s in-house ExOne S-Max 3D Sand Printer advances mold and core production with high-precision, speed, and design integrity. Our advanced technology exceeds in producing highly intricate designs, undercuts, and internal passages without the issues of traditional tooling constraints.

WHAT KIND OF CASTINGS ARE AVAILABLE?

Time and accuracy. The ExOne™ 3D sand printing process is super-efficient, with most projects taking no more than a few hours to complete. This alone opens the door to more prototype and small batch projects. We cast aluminum, grey and ductile iron, and ZA12 alloys in both 3D sand for small quantities as well as production volumes with our Alpha Process shell sand molding process. We can even produce hybrid castings using 3D printed cores for complex internal geometry with Alpha Process production molds.

What are the benefits of 3D printing for sand casting with Alpha Foundry?

3D Sand Printing allows for real casting production immediately, without the need to wait on tooling/pattern development. It also allows for complex geometry, fewer cores with less variation due to core assembly, and general casting designs that would be nearly impossible with hard tooling and real-world pattern limitations.

How does Alpha Foundry make 3D Sand Printing competitive for production?

We call cleaning 3D sand prints “depowdering.” Depowdering can become an unnecessarily time-consuming, labor intensive, and costly manual activity that creates a bottleneck compared to the speed of the core printing process. The fastest, most efficient, and careful way to clean 3D printed sandcastings is with ShotShower™. ShotShower™ can not only reduce labor costs but increases quality and lowers scrap rates…and frees up employees for productive work elsewhere in your operations. See hotideasllc.com to learn more.